|

The Ultimate Purge-Blowback Systems |

|

|

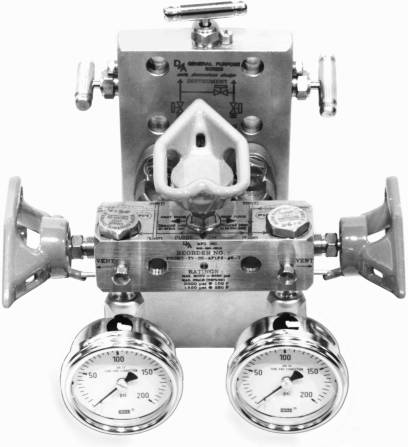

Shown Here: PRGM7 mounted to a GP3FU Manifold |

| Modes of Operation |

|

When either of the service valves are turned to "TEST", the discharge of that flow cartridge is blocked downstream of the pressure indicator (PI). This "PI" was indicating process pressure, but it will now increase to indicate the purge inlet pressure as flow continues through the flow cartridge. The rate of pressure rise is a direct indication of flow rate through the cartridge; thus, serving as a good, positive indicator of two things: 1) Is the cartridge plugged? and 2) Is the purge and process pressure differential large enough? If a more accurate indication of the flow rate is desired, open the vent valve to bring the (PI) down to zero pressure. Then close the vent valve and time how long it takes the flow cartridge to bring the (PI) back up to purge line pressure. Since the purge header pressure is constant throughout the plant, this recharge time should be fairly constant. This vent and recharge procedure can also be used to try and clear a restricted flow cartridge. If it does not clear, then dial "PURGE OFF", vent off the pressure, and replace the cartridge.  |

This is the mode used to remove or replace a flow cartridge or pressure gauge. Use the vent system to bleed off ALL pressure prior to removing a cartridge or gauge.  |

This mode is used to blast the tap lines clean. It is necessary to go on manual control before doing a fast purge. The most common need for this mode is to remove a liquid trap from within a vapor purge system. It is also used to remove sediments that may have collected in the line during a purge system failure.  |

| Specifications | ||

|

Max Ratings: Teflon®: 2500psi @ 100°F 1500psi @ 220°F *Ryton: 2500psi @ 220°F 1500psi @ 520°F * DO NOT USE BELOW 200°F |

Material: All wetted and exposed parts are 316SS Codes: Barstock, A479 - 316, A276-316; Cast, ASTM-A743 CF3M, ASTM-A-351 CF3M, A 276-316. |

Design Codes: ANSI B31.1, B16.5, NACE MR-01-75 (special order) |

| Spare Parts | |||

|

Part Description: |

Part Number: |

Part Description: |

Part Number: |

|

Flow Cartridge # 2 Flow Cartridge # 4 Flow Cartridge # 6 Flow Cartridge # 8 Ryton Face Seal (PRGM7 Only) |

TSOFLOW2MZ TSOFLOW4MZ TSOFLOW6MZ TSOFLOW8MZ H80AMA02PZ |

Viton® O-ring Cart. Seat Seal Teflon® O-ring Cart. Seat Seal Viton® O-ring Cart. Seal Teflon® O-ring Cart. Seal |

D71AAA05PZ D70AAA05PZ D71AAA06PZ D70AAA06PZ |

Teflon® is a registered trademark of DuPont.

D/A Manufacturing Co., Inc.

Hwy 86 East or P.O. Box T

Tulia, TX 79088-0920 USA

Phone: (806)995-2316

FAX: (806)995-4601

DWF