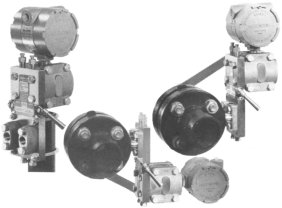

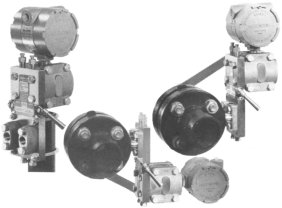

Typical Installations

|

- 2-1/8" to 2-3/16" center to center all flanged connections.

Line side provides threaded connections for mounting standard

oval flanges furnished with the transmitter or D/A's investment

cast adapter flanges

- A pair of purge or bleed valve connections at both top and

bottom for versatility and convenience

- Straight-through roddable porting - no stagnant cavities

- In-line replaceable soft seats and seals

- PVC coated directional arrowhead handles with positive stops

- Bonnetless construction with unique tapered plug design

- Barstock construction

- No metal to metal contact

- Adjustable packing nut stops interport and stem leakage

- Optional integral steam heating system

|

|

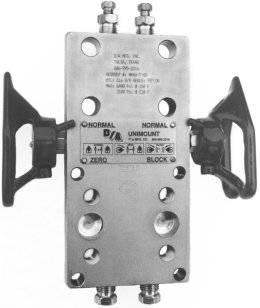

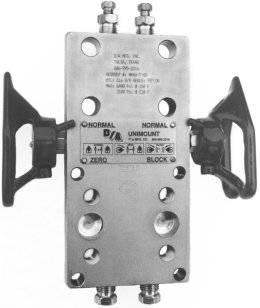

The D/A MM4U is a universal

mounting 3-valve manifold providing the 3 required functions by simply

dialing NORMAL, ZERO or BLOCKED. This same unique manifold excels in

the ability to perform as both a manifold and a sturdy transmitter

mount for either remote mounted or meter run flange mounted systems.

It serves well in liquid or vapor service, and in both systems, offers

easy 360 degree access to the 4 transmitter mounting bolts.

The Unimount design allows the completion of all

piping prior to installation of the transmitter. The built in

manifold mounting system permits easy removal of the transmitter

without disturbing the process lines or mounting connections.

The D/A UNIMOUNT - World's Most Universal Mounting Manifold

|

|

Operation

|

Normal Mode

Zeroing Mode

Isolation Mode

Note: Because of the unique fool-proof design,

the Zeroing Valve and Blocking Valve handles can be dialed to their

respective positions in any order without causing improper operation.

|

Normal Mode

With both valve handles in the normal position, the MM4U is in the

normal mode with both process inlets open and the equalizing

port blocked.

Zeroing Mode

By dialing the Zeroing Valve handle to the ZERO position, the MM4U is

automatically switched to the zeroing mode which completely and

properly prepares the transmitter for zeroing by (1)first blocking one

inlet impulse line and (2) then opening the equalizing port which

bypasses the blocked inlet to equalize the P cell at process

pressure. Because it basically operates like a 3-way valve, this forced

zeroing sequence provides fool-proof operation and safety. After

correcting for zero offset, the transmitter is returned to service by

simply redialing the handle to the NORMAL position which, again,

correctly sequences back to the service mode by closing the equalizer

first and then reopening the blocked inlet.

Isolation Mode

By dialing the Zeroing Valve and Blocking Valve handles to the ZERO and

BLOCKED positions respectively, the MM4U is automatically switched to

the islolation mode where both inlets are blocked and the

equalizing port is closed. The transmitter is now safely isolated and

prepared for field servicing, recalibration or removal. The transmitter

is returned to service by simply redialing the handles to their NORMAL

positions which, again, correctly sequences back to the service mode by

leaving the equalizer blocked and reopening both inlets.

|

|

Specifications

|

Max Ratings:

Teflon:

6000psi @ -150ºF to 150ºF

3500psi @ 220ºF

Ryton:

6000psi @ 325ºF

2500psi @ 520ºF

Connections:

Flanged instrument x Flanged process

Design Codes:

ANSI B31.1, B16.5, NACE MR-01-75(special

order)

Material Codes:

Barstock, A479 - 316, A276-316;

Cast, ASTM-A743 CF3M, ASTM-A-351 CF3M, A 276-316.

|

Materials of Construction:

Body: 316SS or nickel plated C.S.

Wetted Plug: 316SS

Plug Liner: Teflon or Ryton reinforced Teflon

Face Seals: Ryton reinforced Teflon

Non-Wetted Trim: 303SS

Handle: Cast aluminum arrowhead - PVC coated

Nameplate: SS embossed

Plugs / Bleed Valve:316SS

Exotic materials: Hastelloy C, Monel, Alloy 20,

etc. consult factory.

|